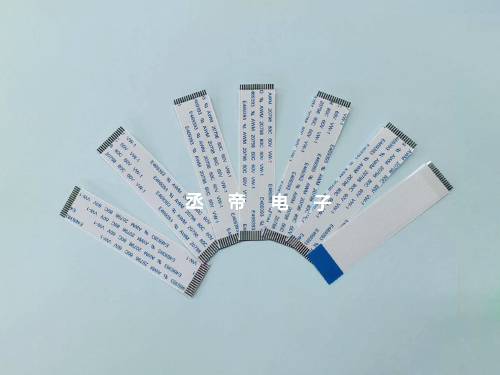

Flexible printed FFC circuit board, also known as flexible circuit board, flexible circuit board, flexible circuit board, is a special printed FFC circuit board. It is characterized by light weight, thin thickness, softness and bendability. Mainly used in mobile phones, laptops, PDAs, digital cameras, LCD and many other products.

Flexible printed FFC circuit board mainly consists of five parts:

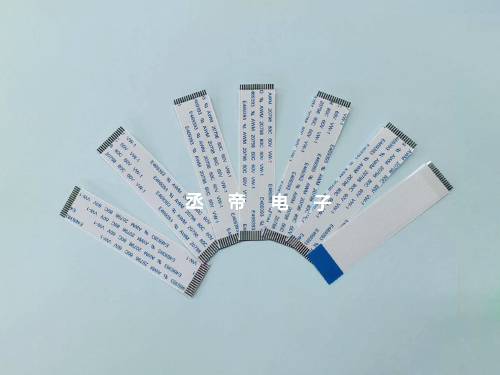

1. Substrate: the common material is polyimide.

2. Copper foil: divided into electrolytic copper and calendered copper.

3. Follow up agent: generally 0.5mil epoxy resin thermosetting adhesive.

4. Protective film: for surface insulation. The common material is polyimide.

5. Reinforcement: strengthen the mechanical strength of flexible printed FFC wiring circuit board.

Flexible printed FFC circuit board can be divided into single-layer board and double-sided board. The differences between the two are described below.

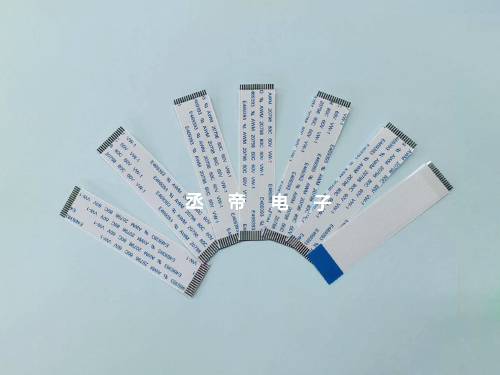

The single-layer flexible plate is a flexible plate with simple structure. From the bottom to the top: substrate, binder, copper foil, binder, protective film. Reinforcement can be added in the lower layer as required.

Both sides of the double-sided board have pads, which are mainly used to connect with other FFC circuit boards. From bottom to top: protective film, adhesive, copper foil, adhesive, substrate, adhesive, copper foil, adhesive, protective film. When the circuit of double-layer board and multi-layer board is more complex and single-layer board cannot be wired, double-layer board or multi-layer board is needed.

The difference between multilayer board and single-layer board is that the multilayer board increases the through-hole structure to connect the copper foil layers. From bottom to top: base plate, binder, copper foil, binder resist film.