FFC cable is a kind of soft flat cable. We can choose the number of FFC wires and the size of the spacing of the wires at will. FFC cable is to make the connection more convenient, which can greatly reduce the volume of electronic products, help businesses improve production efficiency, and help manufacturers reduce production costs. FFC cable manufacturers all know that FFC cable is suitable to be placed in the middle of the main board of electronic products and their moving parts, between PCB boards and as the transmission line of data between electronic devices. Therefore, FFC cable is widely used in various types of printers, scanners, copiers, audio, plotters, televisions and other electrical equipment and the signal transmission lines and connecting lines between their motherboards, which can be seen everywhere in the contemporary era of science and technology.

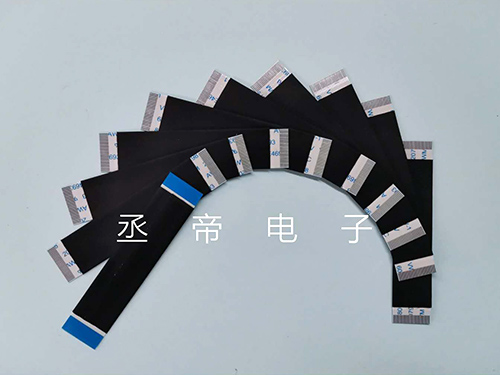

FFC cable arranger has excellent flexibility, can be used in various occasions flexibly, and can be folded and bent freely. It is no problem to do tens of millions of slides. Not only that, FFC cable arranger is easy to use by the supplier, and its volume is also very small. The wiring procedure is very simple and easy to understand, and everyone can operate it by himself.

The convenience of FFC line arrangement to production

FFC cable arrangement is small and light. The original design of FFC cable arrangement board is used to replace the larger wire harness. In the current cutting edge electronic device assembly board, FFC cable arrangement is usually the only solution to meet the requirements of miniaturization and mobility. FFC (sometimes called flexible printed circuit) is to etch copper circuit or printed polymer thick film circuit on polymer substrate. For thin, light, compact and complex devices, the design solution includes from single-sided conductive circuit to complex multilayer three-dimensional assembly. The total weight and volume of FFC are 70% less than that of traditional circular wire harness. FFC cable arrangement can also increase its strength by using reinforcement materials or lining plates to achieve additional mechanical stability.